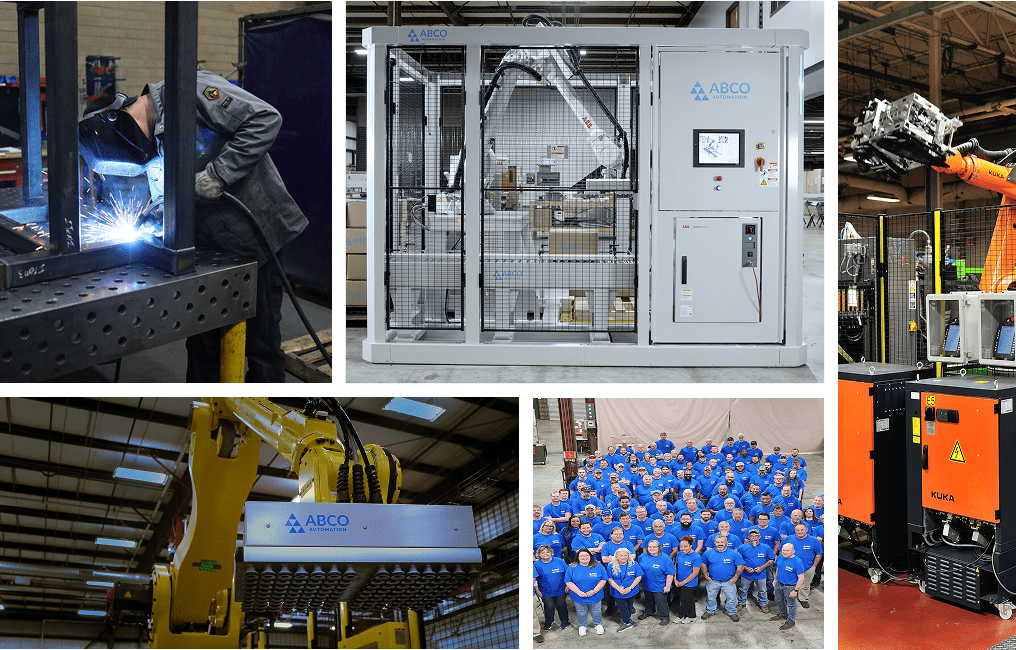

Discover why ABCO is the right choice for your business

47 Years in Automation

With 47 years of experience in automation, ABCO has been at the forefront of the manufacturing industry since 1977.

.svg)

Best in Class Engineering & Manufacturing

When it comes to custom engineering and design solutions, we are the unbeatable partner with a proven track record of delivering top-notch quality and unmatched scalability.

.svg)

U.S.-Based & Employee-Owned

We take pride in being a North Carolina-based business that is owned and operated by our dedicated employees. Trust, reliability, and innovation are the pillars on which our company stands.

Whether you're seeking to streamline your operations, drive growth, enhance productivity, bring together diverse components, or seek professional assistance on the field, ABCO is your ultimate business solution provider. With our cutting-edge technology and extensive expertise, we offer tailored solutions that perfectly align with your unique business needs. Trust ABCO to automate your processes, scale your operations, construct a solid foundation, bring together all the necessary components, and provide prompt and reliable field service and support. Experience the ABCO difference and witness how we can revolutionize your business.

Our Engineers Specialize in Automation for Your Industry

Our team of expert engineers specializes in providing tailor-made automation and manufacturing solutions to a wide range of industries. With a successful track record, we have optimized logistics, enhanced efficiency, and implemented seamless processes to drive growth and success for our clients.

Food & Beverage

Since 1977, we've partnered with the biggest names in F&B to implement filling systems, packaging, palletizing, and more.

Logistics

Life Sciences

Automated Solutions to Improve Your Bottom Line

Factory automation fueled by robots provides many benefits to manufacturing companies, including higher productivity, lower costs, increased worker safety, and improved quality.

Lower manufacturing & labor costs

Increase employee safety & reduce liability

Improve quality and consistency of results

Application Experience Examples

Inspection

Laser Marking

Grinding

Machine Tending

Discover the latest in

automation design and robotics

.png)

Maximize Contract Manufacturing Success with Industry-Specific Expertise

Improve your contract manufacturing with ABCO Automation's industry ...

-1.png)

ABCO Automation: Enhancing Competitiveness with Cost-Effective Solutions

Discover how ABCO Automation's competitive pricing and focus on Tota...

.png)

Engineering Capabilities: A Critical Factor in Evaluating Contract Manufacturing Partners

Discover why ABCO Automation's engineering capabilities are crucial ...

.svg)

.svg)

.svg)

.svg)